Digital Business Innovator

LG CNS

Latest News

Business

- Cloud

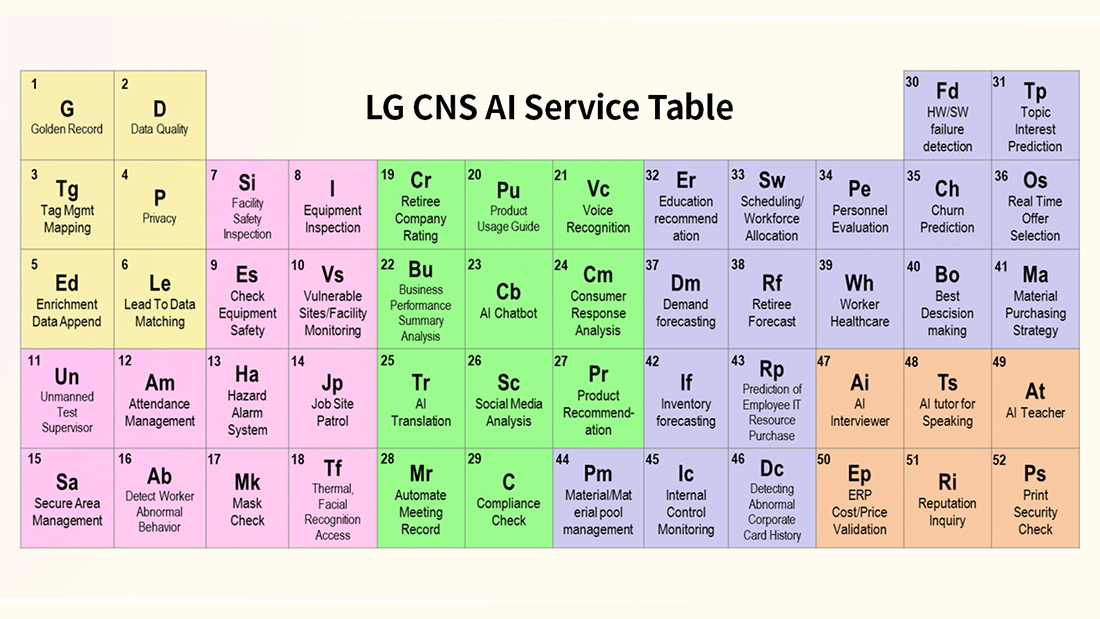

- AI/Big Data

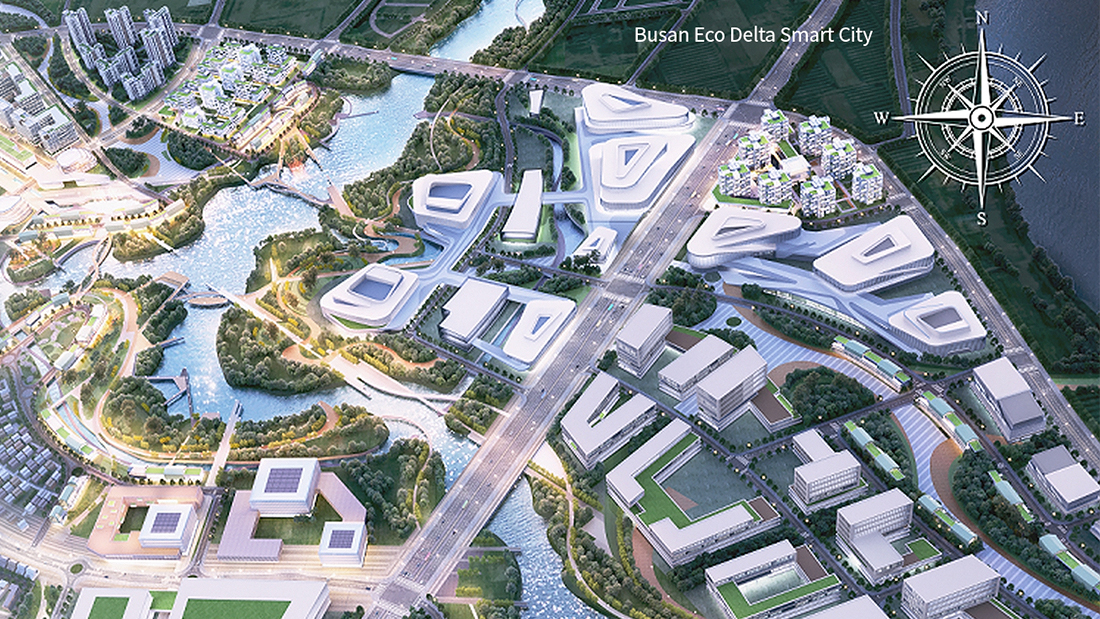

- Smart City

- Smart Factory

- Smart Logistics

- DX in Finance

- DX in Public

- Digital Customer Experiene

- Web3

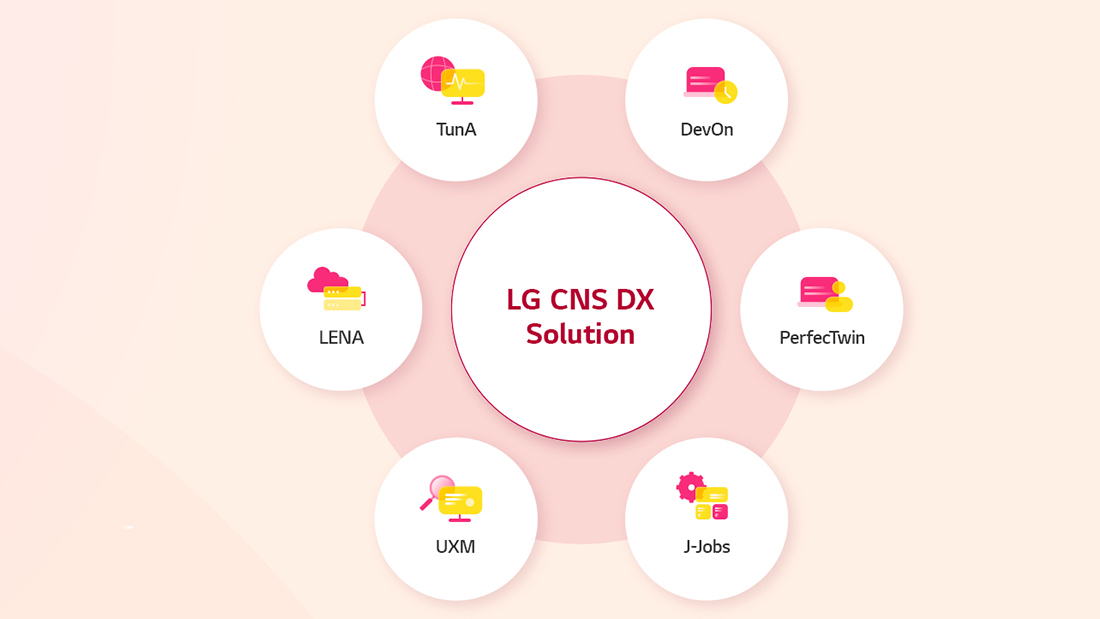

- DX Solutions

- Security

LG CNS provides optimized cloud services across many business areas

with public cloud, multi/hybrid cloud expertise.

LG CNS provides optimal services through collection

and storage of big data and verified AI services.

LG CNS is creating a future city for a better life,

focusing on mobility and data.

LG CNS is leading intelligent factory with new IT such as AI, big data,

and IoT, and is changing the paradigm of manufacturing sites.

LG CNS is leading the smart logistics market by building a digital warehouse

with an optimal combination of IT and facilities.

LG CNS is leading the DX in the financial industry

with its expertise in the financial industry and IT such as cloud, AI, and blockchain.

LG CNS is contributing to strengthening national DX competitiveness

through stable nationwide IT services.

LG CNS is innovating customer experience

in a digital environment using new DX technology.

LG CNS creates customer value through practical services

such as digital identity authentication and digital asset trading, etc.

Meet the LG CNS’s DX solutions based on new information technologies.

LG CNS provides integrated security services,

ranging from security consulting to implementation, operation, and control.

Sustainability

Priorities

LG CNS is strengthening sustainability management by practicing ESG.

Environmental Management

LG CNS practices environmental management

with eco-friendly technologies.

Social Contribution

LG CNS will build a better world through DX technology.

Growing Together

LG CNS grows together with partner companies based on trust.

Fair Trade

LG CNS grows together with partner companies based on trust.

Jeong-do Management

LG CNS pursues ethical management based on

LG’s unique behavioral method of Jeong-Do management.